On 1 March 2021, the Ecodesign and Energy Labelling Regulations will come into force for all the devices referred to as Lot 12 by the European Commission’s Directorate for Energy: commercial refrigeration equipment for displaying and selling fresh and frozen products .

The need to comply with Ecodesign obligations and affix a label is an absolute novelty for this product category. To facilitate an understanding of the significance and importance of an energy label in this sector, EPTA, a producer affected by these new obligations, has organised an event with some retail stakeholders. Francesco Scuderi – Deputy Secretary-General of Eurovent – participated to explain the creation, motives and interpretation of the future energy label, as well as the two Directives’ consequences for the market

Ecodesign and Energy Label: two Directives, one objective

The European energy efficiency policies for products connected to the use of energy have numerous legislative instruments, some of which are mandatory and others voluntary. The mandatory ones in the Member States include those that are perhaps the two most famous Directives for energy efficiency, namely the Ecodesign directive (or eco-compatible design) and the Energy Label Directive (or energy labelling).

The first imposes the determination and imposition of minimum, stringent energy consumption requirements of products. The second defines the rules for the label specifying the energy efficiency of a product. The two Directives are connected in terms of the effect they have on the market.

The Ecodesign Directive (Directive 2009/125/EC) regulates the minimum energy consumption characteristics for all the products connected to the use of energy, that is, every good that has an impact on energy consumption during its use. Implemented by all Member States, the Directive refers to products that are manufactured in the European economic area, as well as those imported from other countries. The ultimate aim of the Directive is to improve environmental impact in terms of the energy consumption of products on the market. Those products that do not meet the Ecodesign requirements for their category cannot be placed on the European market. The Ecodesign Directive mainly affects the production side, bringing the industry to sell increasingly efficient products. It also acts as selection for that which arrives on the market: products that are poorly designed, and consequently consume too much energy, are eliminated from it.

On the other hand, the Energy Labelling Directive (Directive 2010/30/EU) defines a series of labelling requirements for products related to energy consumption. As replaced by the Energy Labelling Framework Regulation (EU Regulation No.2017/1369), it classifies products into classes A to G based on their energy efficiency. It also indicates other information related to environmental impact that may be useful to the consumer during the purchasing process (e.g.: water consumption, noise, etc.).

The label is therefore a tool designed to provide consumers with information that allows them to make an informed purchase, promoting the choice of items with lower consumption and high performance. It does not eliminate products from the market, but allows consumers to purchase increasingly efficient products thanks to the additional information.

Although the two Directives refer to different stakeholders, producers and consumers, they are part of a single strategy: to increase the energy efficiency of products on the market. This effect is increasingly important as the products in question become more widespread and the greater the technological potential for improvement.

What will change for the buyer?

Following the two Regulations’ entry into force, buyers can expect to find an energy label on each appliance, even during the offer phase. Francesco Scuderi explained, “Surely the first two energy classes – A and B – will be empty for the first few years, because they are destined for the best available technologies which are not yet available. The best appliances will probably be in class C. A change of perspective is therefore required of buyers: those who buy a device in class C or D in 2021 must understand that they are buying the best the market has to offer at that moment. Innovation and the evolution towards ever-better appliances over time will allow filling the first two classes as well”. This is precisely the operating mechanism of the energy label: to encourage manufacturers to climb the ladder, putting evermore efficient appliances on the market.

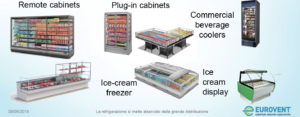

An important observation: “The evaluation of the energy consumption of each type of appliance and, consequently, the identification of different energy classes on the label was applied considering different parameters: type of furniture (plug-in or remote); exposure temperature (low or medium); type of product to be displayed (meat or dairy products or other). This has allowed defining energy classes and minimum ecodesign requirements suitable for each type of appliance and intended use. This is a very important detail for Lot 12: even though the devices considered are homogeneous in terms of sales destination, they are not homogeneous in terms of technology and therefore possible energy consumption“.

What will change for manufacturers?

Manufacturers will have to submit the devices they place on the market to energy efficiency tests which will be the basis 1) for verifying compliance with the minimum Ecodesign requirements and 2) defining the energy class to be reported on the label. Scuderi explains, “The reference standards for testing this type of device are EN ISO 23953 for supermarket displays, EN ISO 16902 for bottle coolers and EN 16901 for ice cream freezers. They define how the measurement of energy consumption must be carried out and differentiate precisely between the categories indicated above: plug in/remote, low or medium temperature, products intended for display. The EEI value – energy efficiency index – which derives from these measurements is the key value that will determine whether the appliance meets the Ecodesign requirements and its energy class“. The Ecodesign Directive is neutral with respect to technology. That is, it does not oblige the manufacturer to use one technological solution or another, but only to respect energy consumption limits. In practical terms this means, for example, that there are no requirements relating to the refrigerant to use, nor on the use of refrigerated cabinet closures or lack thereof. “It is up to the manufacturer to decide which technology to use to reach the only mandatory target: the minimum energy efficiency requirement“.

Efficiency data and other technical information will be included in the EPREL database (EU Product Database for Energy Labelling), established with the dual objective of being able to be used by the control authorities for market surveillance activities and to make the list of labelled products publicly available online.

Certifications for third parties: an extra guarantee

The declaration of conformity for the Ecodesign and Energy label is the responsibility of the manufacturer and in most cases is based on a self-certification before placing the product on the market. Market surveillance plays a fundamental role in ensuring that the statements made by the manufacturers in terms of equipment performance also reflect the truth. However, the Supervisory Authority is not always able to conduct thorough checks on products at the same rate with which they reach the market, so the buyer has no choice but to trust what the manufacturer has declared. Or the buyer can request the submission of certifications by third parties (voluntary and non-compulsory). In this case, a third-party body (accredited according to the standard ISO 17065) that has no relationship with the manufacturing company has the trial and efficiency tests conducted by a further third-party laboratory (accredited according to the standard ISO 17025) on the appliances according to the official standards to verify that the manufacturer’s declarations respect the actual performance. In this case the company is certified by the third-party body. The institutions that conduct specific certifications for this sector include Eurovent Certification, an independent unit of the Eurovent association. “Eurovent certification is very strict. Among other things, it also includes regular checks on the statements of the products declared by the certified companies to monitor that what has been declared is sold and that what is sold has been declared. If there are irregularities, the certification can also be revoked in extreme cases“. The costs of a third-party certification fall on the manufacturer requesting it. In this regard, Scuderi states: “The value of a certification goes far beyond the accreditation in itself. For example, some tenders provide an additional score for companies or products with third-party certification. Certification is therefore an added value for the company and can improve its market positioning, as well as being constant and objective monitoring of its work“.