In an energy provisioning situation increasingly determined by the fluctuation of renewable sources, the possibility of efficient heat storages can share in assuring stability and in using renewable energies wherever they are more available and cheaper, meanwhile relieving the power grid from peak loads.

In an energy provisioning situation increasingly determined by the fluctuation of renewable sources, the possibility of efficient heat storages can share in assuring stability and in using renewable energies wherever they are more available and cheaper, meanwhile relieving the power grid from peak loads.

Nowadays, a thermal battery considered efficient, cheap and reliable is the ice slurry. The ice slurry is available both as energy storage means and for conditioning and refrigeration applications, for the displacement of the thermal load and then for the integration of high shares of renewable energies into the cold production system. The decrease of electric load peaks and the refrigeration shift towards moments of low electricity costs contribute in the energy cost reduction for many customers and, ultimately, in the enhancement of the cold production efficiency.

The ice slurry consists of a sort of mixture of water and ice crystals. As a biphasic refrigerant-carrier fluid (liquid-solid), it features high thermal exchange efficiency due to the large surface area offered by ice crystals in suspension. Since derived from water, it can be considered a natural refrigerant. The most known ice slurry production processes provide for scraped or brushed surfaces. At ILK in Dresden – Institut für Luft- und Kältetechnik – they have applied for a long time now the vacuum ice slurry production method and the work ILK is carrying out on this issue was presented in October at Chillventa eSpecial by Mathias Safarik, Manager of the applied engineering division, ILK.

Vacuum ice slurry

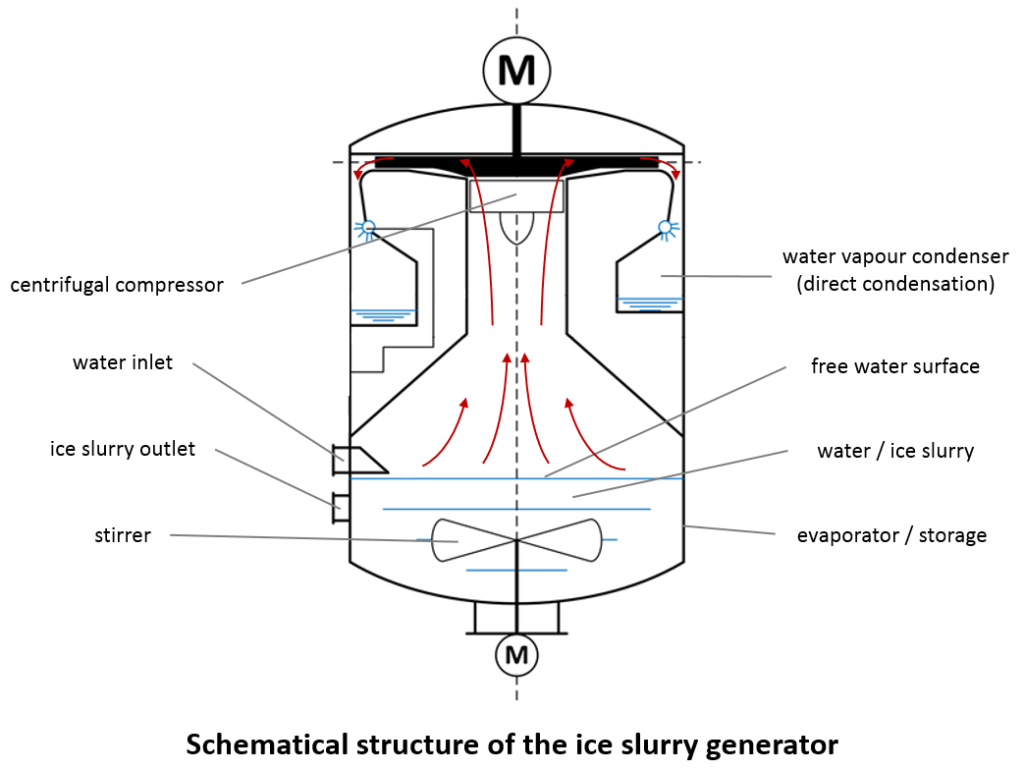

This technology of ice slurry production exploits the natural phenomenon of the triple point of water, that is to say that univocal point of temperature and pressure where the three physical statuses of water coexist in a dynamic balance. Energy is subtracted to the surrounding liquid through the evaporation of single molecules from the water surface. In vacuum, the water evaporation at the triple point occurs at about -0.5°C: hand in hand with the evaporation of molecules, other molecules of water freeze and form ice particles. To exploit this phenomenon for the ice slurry production, the water steam is sucked by the vacuum container and the ice formation process proceeds. In the system developed by ILK, it is compressed by special turbo-compressors purposely developed and re-condensed in a standard steam compression cycle where water is the refrigerant. The low water steam density at a pressure of 6mbars is naturally a specific difficulty for the compression process. The compressor developed by ILK Dresden is a centrifugal compressor with maximum 1MW output that is used also for the desalination of sea water.

In this closed system, the heat by evaporation must not be supplied by external exchangers but it is the latent heat of the vacuum water. This, combined with an evaporation taking place at a temperature very close to the freezing point, makes the system extremely efficient. The ice slurry stocking can be integrated into existing cold-water nets or be coupled with a water-based chiller. During the battery charging – that is to say during the ice formation – the refrigerated water is used to dissipate the condensation heat of the process.

During a high cooling demand, water is refrigerated by melting ice particles. This happens inside a conventional external heat exchanger. The achievable discharge capacity of the battery can be customized according to the particular application and customers’ requirements, selecting a common suitable plate heat exchanger.

Applications and advantages

Ice slurry systems can have different applications:

- Cold stocking to satisfy refrigeration demand peaks or to reduce electrical load peaks;

- Implementation of refrigerating cells that extend the capacity in existing refrigeration nets and increase the supply reliability

- Real stocking of renewable energies (“Power-to-Cold”)

- Higher flexibility of combined heat-cold systems and energy (Trigeneration)

- As refrigerant for industrial cooling or air conditioning at about 0°C.

The ice slurry-based stocking system provides various advantages compared to cold water or standard ice:

- Ice slurry has a high accumulation density and therefore, with the same generated cold, minor volumes are necessary. While cold water can accumulate about 7kWh/m3 (between 6 and 12°C), ice 50kWh/m3, ice slurry succeeds in accumulating up to 54 kWh with 60% of ice particles. For the same cold accumulation capacity, 10 m3 of water, 1.4 m3 of ice and 1.3 m3 of ice slurry are necessary

- Although above-reported numbers are not very different between ice and ice slurry, we must consider that the charge/discharge flexibility of the ice slurry battery is much higher than the ice one. The operation of the ice slurry battery is very flexible: no complete battery discharge is necessary before recharging the stockage, a quick shift from charge to discharge and vice versa is possible

- Highest efficiency of all processes that generate ice;

- No glycol circulation required, the system can be easily integrated into (existing) cold water nets

- Ice particles are produced through water evaporation on the surface inside the evaporator. This means that, compared to other ice slurry generation processes, no ice scraping from the heat exchanger’s surfaces – then less abrasion and maintenance effort

- The heat exchanger is not inside the battery, then storage, charge and discharge capacities are fully independent one another and freely selectable

- The water/ice phase change material is cheap, ecologic and does not decompose.

Besides, worth reminding ice slurry can be pumped. It can be directly pumped as refrigerant in the heat exchangers of refrigerating cells. As it absorbs heat, the ice slurry maintains its temperature whereas its status changes, with the consequence that the exchange remains efficient along the whole evaporator. These features make ice slurry very useful for industrial applications that need temperatures close to zero, such as breweries, dairies and so on. Especially in the food industry, the ice slurry can be an excellent secondary refrigerant to be used directly in circuits wherever in the primary circuit ammonia for instance flows. Being just water, it can be pumped without hesitation in food processing areas.

Ice slurry: to heat, too

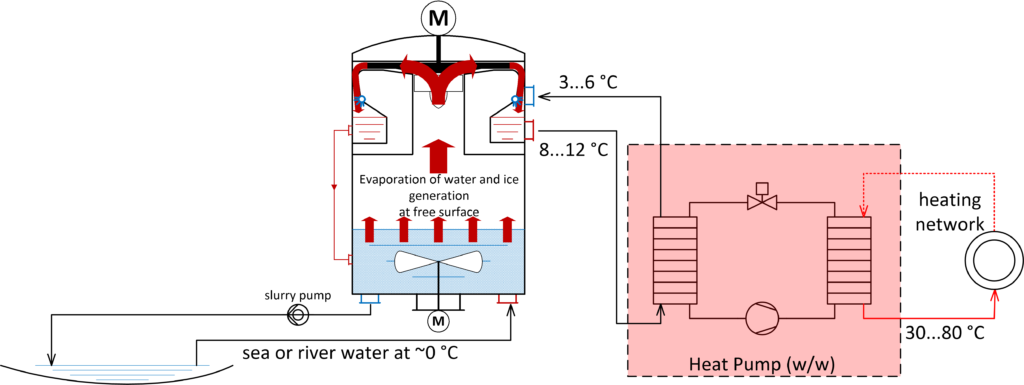

Heat pump systems are crucial component for the increase of the renewable energy share and are becoming increasingly popular thanks to their efficiency. Currently, prevailingly air heat pumps are used as, compared to water ones, they have minor investment costs and less committing installation procedures. However, they are also less efficient, especially when air reaches the lowest temperatures, in other words in periods when the heating demand is higher. Water heat pumps better satisfy higher heating demands but they need a water source for the thermal exchange. The water source might sometimes be, wherever accessible, a natural or artificial water tank. This solution is still scarcely exploited at our latitudes owing to the risk of water basin freezing in winter period. Using ice slurry as first element in cascade with a heat pump, we can use easily accessible natural or artificial water tanks as thermal energy sources, as they have water temperatures slightly above zero, too. Owing to the constant heat source temperature, and higher versus air heat pumps, you achieve a significant advantage in terms of energy efficiency. A similar circuit might ideally have the structure shown in figure 4, where the ice slurry battery acts as interface between the natural water basin and the heat pump.

Further information:

- ILK Dresden – Ice slurry project (in English): https://www.ilkdresden.de/en/project/ice-slurry-generation/